How the HDII Makes your Angle Grinder Safer

Why the HDII Makes Your Angle Grinder Safer

One of the biggest reasons people choose the HDII is safety, especially when compared to traditional thin cutoff wheels.

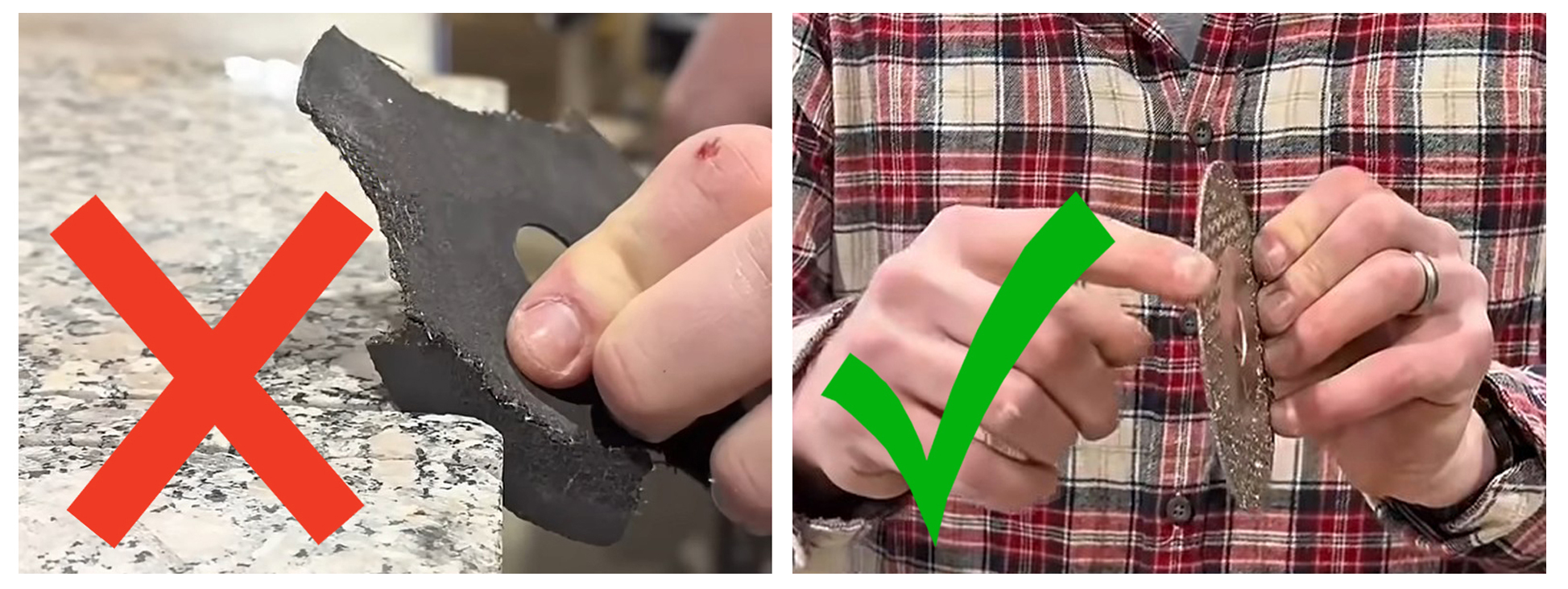

At the hardware store, you’ll usually be pointed toward a thin carborundum cutoff wheel. These wheels are fast, but they’re fragile. With just a little side pressure, especially in hard materials like granite, masonry, or steel, they can shatter. When that happens on a grinder spinning at 11,000 RPM, fragments go everywhere. Best case, you ruin the material. Worst case, one of those pieces finds you.

The HDII solves that problem by design. Instead of a thin abrasive wheel, it uses 46-grit diamond bonded to a hardened steel core. Diamond coverage on both the face and the edge means you can cut, grind, and clean up material without worrying about side loading.

If you make a mistake, and everyone does, the result is a damaged workpiece, not a broken wheel. The steel core and diamond coverage allow the wheel to stay intact even when things don’t go perfectly, reducing the risk of sudden wheel failure.

That combination of diamond grit and a steel core is what turns a grinder into a more predictable, controlled tool on the jobsite.

Watch the video below to see the difference in action, then check out our available HDII sizes below.