Need to Cut Wood?

Need to cut wood?

Then you need a saw blade. For many people, that blade is the first one they see at the local hardware or big box home improvement store. That’s a great way to choose the wrong saw blade. Here’s why - At first glance, circular saw blades do look eerily similar to one another – teeth attached to a round metal disc. But look a little closer and you’ll see that there are, in fact, some big differences between blades. Let’s take a look.

What kinds of Saw Blades are there?

For beginners, there are two basic kinds of circular saw blades – one that can cut with the grain and one that can cut across the grain.

Think about cutting a 10’ long 1” x 6” piece of trim board:

- You are CROSS CUTTING if you are cutting the 10’ long board down to 8’ long. You are cutting across the grain or fibers of the wood. CROSS CUTTING is typically the the shorter cut to make, but it is also more difficult to prevent chipping and 'blow out'.

- You are RIPPING if you are cutting the 6” wide board down to 4 wide”. You are cutting 'with' the grain or fibers of the wood. RIPPING is typically a cleaner cut but much longer and more difficult to keep straight.

Photo 1: Cross Cutting Oak.

Photo 2: Ripping Down a 2x4

Cross Cutting Blades

What makes one Cross-Cutting Blade better than another.

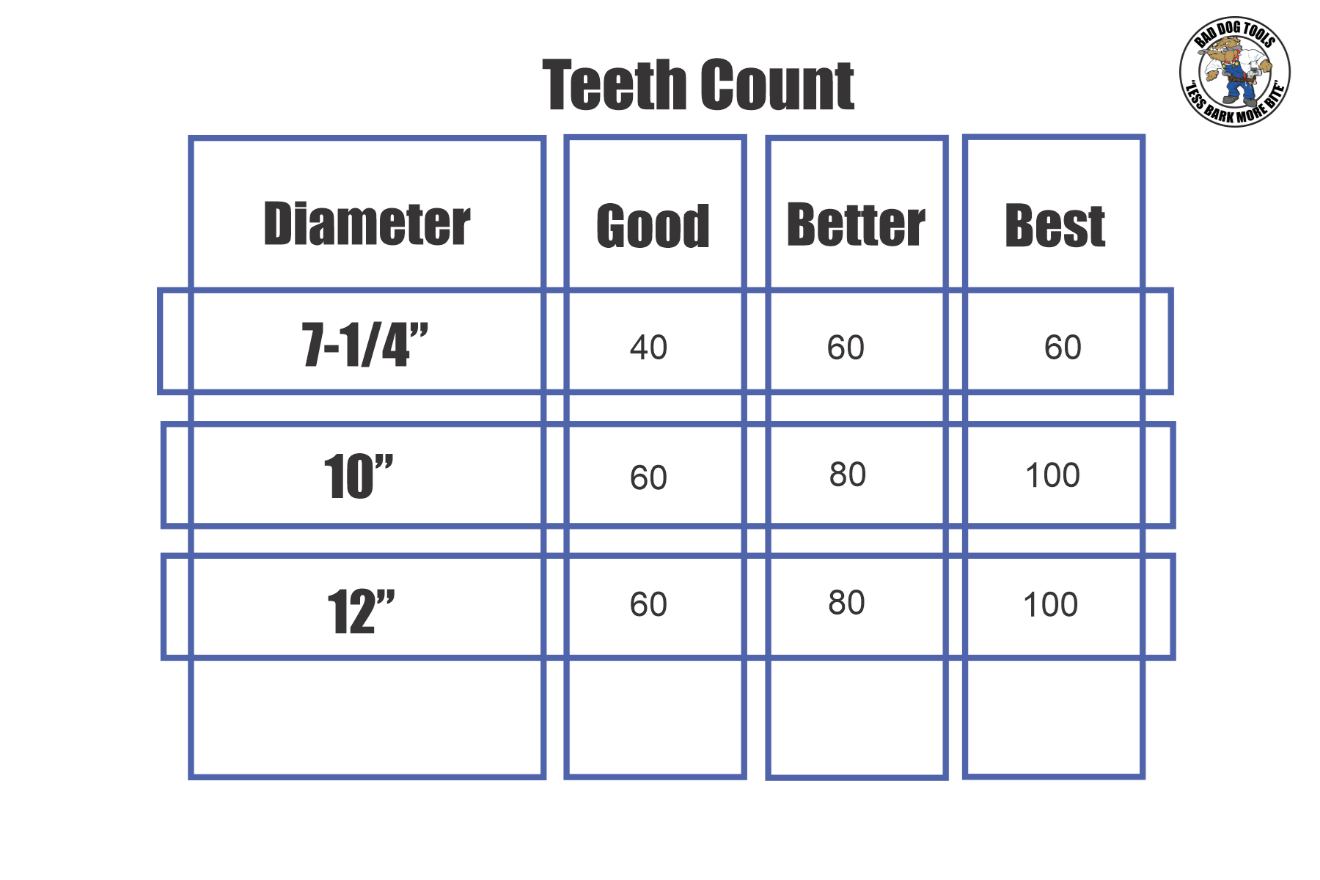

Circular Saw Blades designed for CROSS-CUTTING have lots of teeth – the more the better. A good quality 10” blade should have 80 or more teeth. At 100 teeth, the 10” Bad Dog Saw Dog Blade has got a great set of choppers for exceptionally smooth cuts.

Besides teeth count, is there anything else that I should look for when choosing a cross-cutting circular saw blade?

Besides teeth count, is there anything else that I should look for when choosing a cross-cutting circular saw blade?

There is no question that using a saw blade is dangerous. The best saw blades include features that work to prevent mishaps. One of those features is called “Anti-Kickback” teeth. Kickback is always caused by human error in feeding the piece of wood into the blade either too quickly or at an angle. The piece of wood “kicks back” or flies at an incredibly high rate of speed into the operator – that’s you. The alternating angles of “Anti Kickback Teeth” help keep the wood stable as it’s fed through the saw. Beyond that – keep an eye on your fingers and always wear protective eyewear.

Ripping Blades

But I have to RIP a piece of trim. What about Ripping Blades?

But I have to RIP a piece of trim. What about Ripping Blades?

A 10” RIPPING circular saw blade, on the other hand, has only 20 to 30 teeth. That’s a big difference – but, as we learned above, these blades are doing very different jobs.

But aren’t they both cutting wood – why is the number of teeth important?

It comes down the grain of the wood. Cross Cutting or cutting across the grain of the wood is a little like chopping down a tree in that you are severing the fibers that literally hold the tree together. Ripping is cutting with the grain and it typically measured in feet rather than inches like cross-cutting.

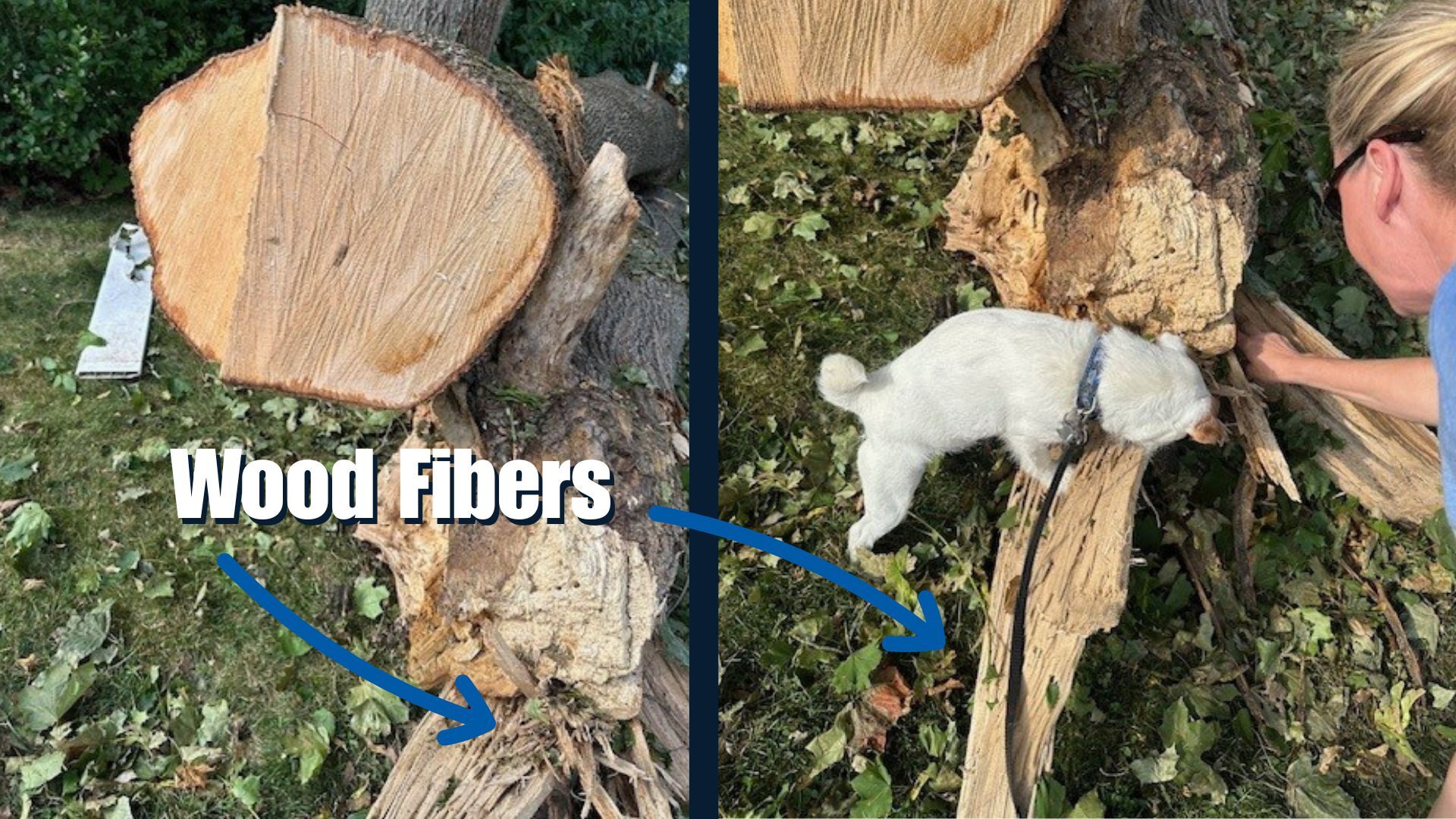

Is a tree really made up of fiber?

Yes, a tree really is made up of fibers. If you’ve ever seen a tree that’s fallen down in a storm like a tornado or hurricane it is likely that you’ve seen a splintered tree. The splintered branches and trunk are the result of the fibers breaking. Imagine the force that it takes to do that and you’ll understand why cross-cutting blades need so many teeth.

What else should I know about the number of teeth on the blade that I’m using?

The number of teeth on a saw blade dictates the FEED RATE for the material that you are cutting.

What is FEED RATE?

The motor on a table or circular saw is not variable speed. The variable, then, is how fast you feed material into the saw. You’ll be rewarded for your effort in determining feed rate with a cut that’s clean with no burning and no chipping on the underside.

Is there anything else I should know about Cross Cutting?

The strength of those fibers, which vary depending on the species of wood that you are cutting, make cross-cutting a tricky job. There is the possibility of kick-back. It’s important to select a cross-cutting blade that includes safety features like anti-kickback design. A circular sawblade should also be regularly sharpened.

Can I sharpen my own sawblade?

DIY’ing it is great but sharpening your own Sawblade is tricky and best left to a pro. That’s why Bad Dog Tools’ Saw Dog Blades come with a LIFETIME GUARANTEE! When the blade is dull or you, oops, chip a tooth, send it on back to us for replacement or repair.

Besides wood, can I cut anything else with a saw blade?

Glad you asked! Bad Dog Tools’ Saw Dog Blade is multi-purpose! Don’t try that with other blades! A Saw Dog Blade cuts hard and soft wood plus melamine, PVC, Plexiglass, Plastic, Carbon Fiber, even Aluminum! It’s a workshop-full of blades in one easy-to-use Lifetime Guaranteed saw blade.

Written by Ann Strong

Technical Engineer & President of Bad Dog Tools